MPU6050从数据采集到上位机通信,AI应用和算法研究前景

在新时代,我们一定要紧跟时代,AI的功能越来越多,越来越强。合理利用AI能极大的提高我们的工程速度,在造轮子的的事情上不要浪费时间。我们可以在此基础上,借助AI,在有了数据的情况下,开始我们的算法研究。在工程应用上,我们一般在有linux系统的开发板上运行代码,我们可以编写好windows格式的代码,将文件拷贝到板子上,修改一下文件路径、配置好环境、连接好硬件。来开始我们的产品开发旅程。开发出一个

流程:

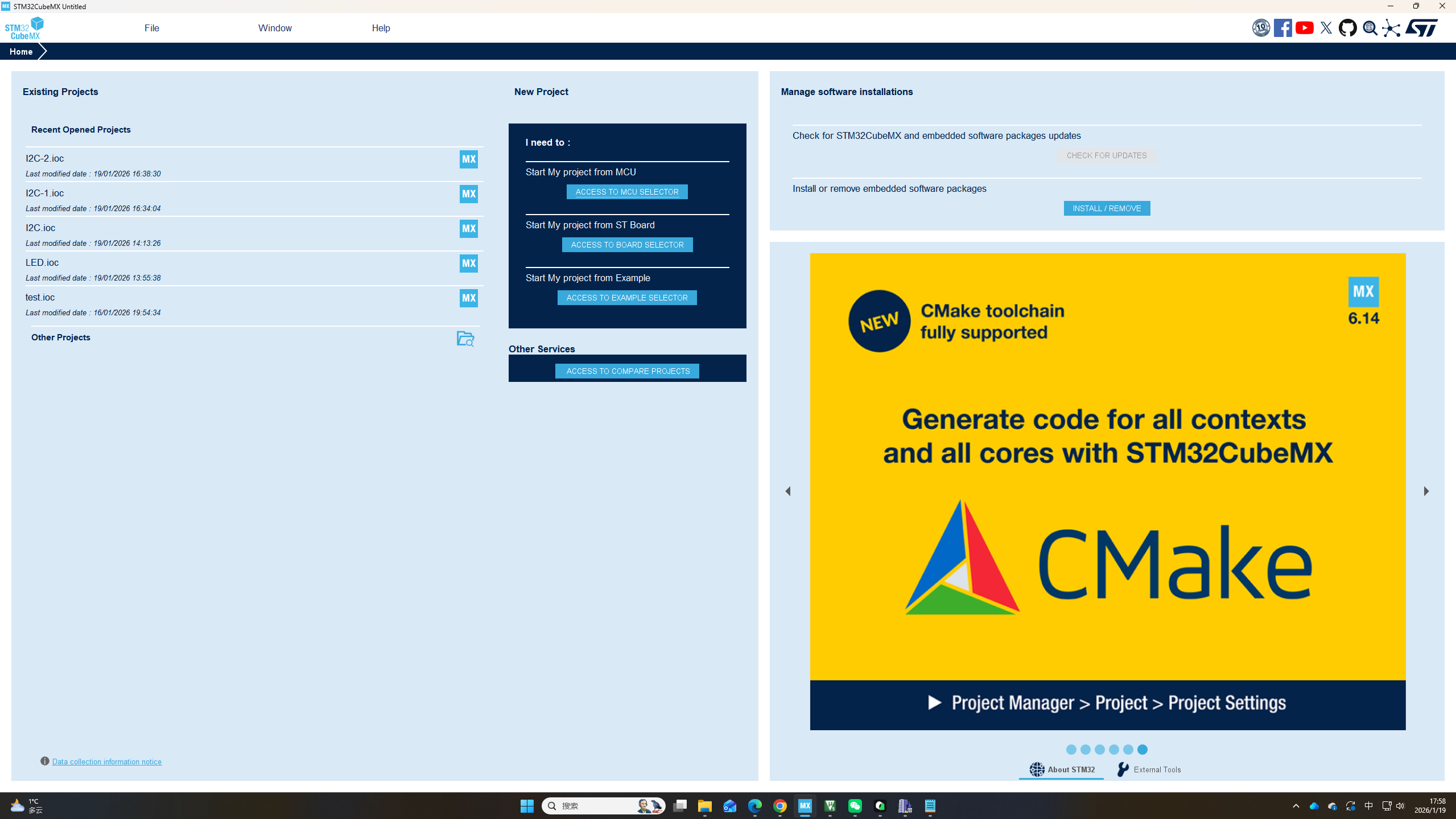

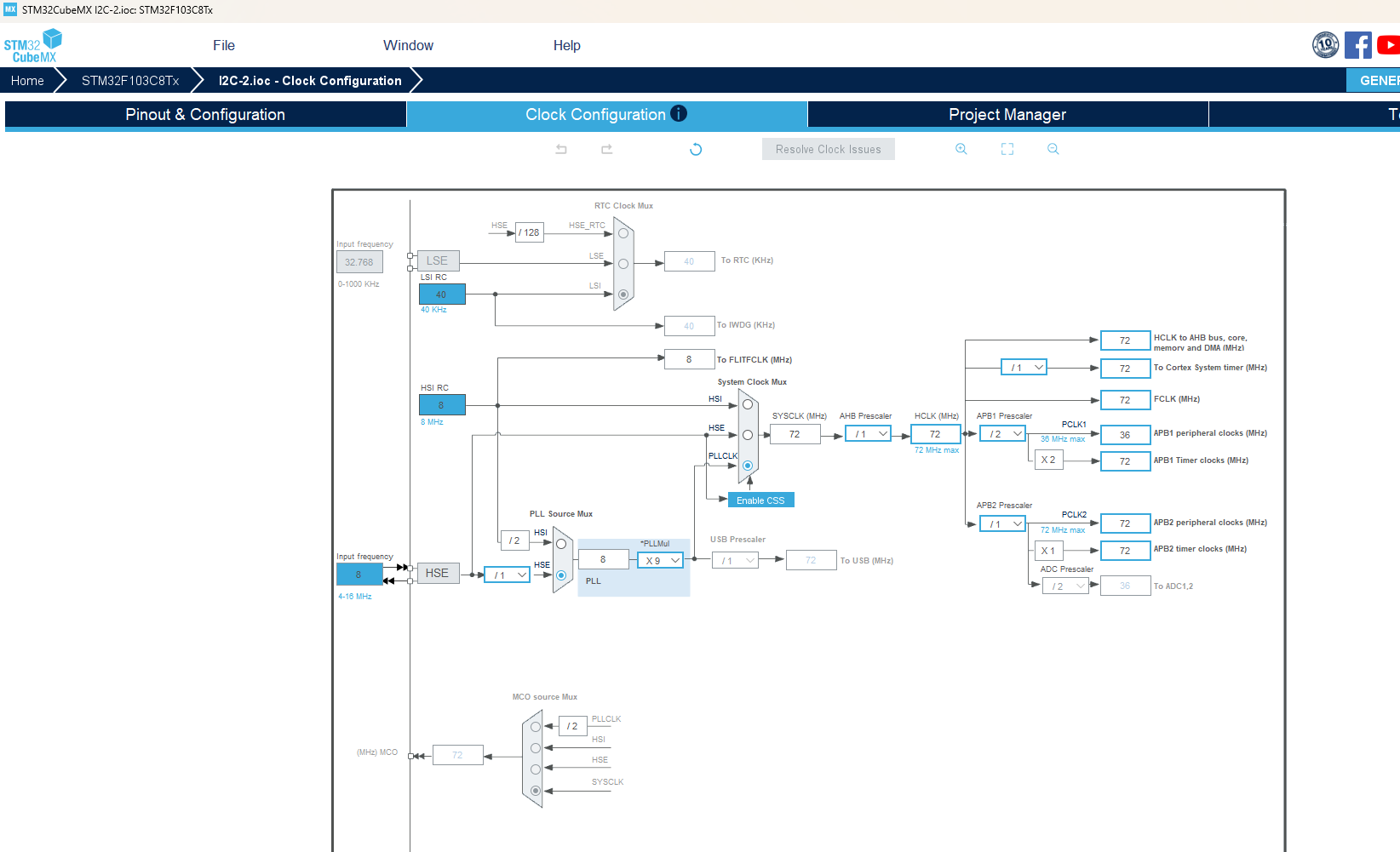

1、在CUBEMX里面创建工程

点击中间的ACCESS TO MCU SELECTOR

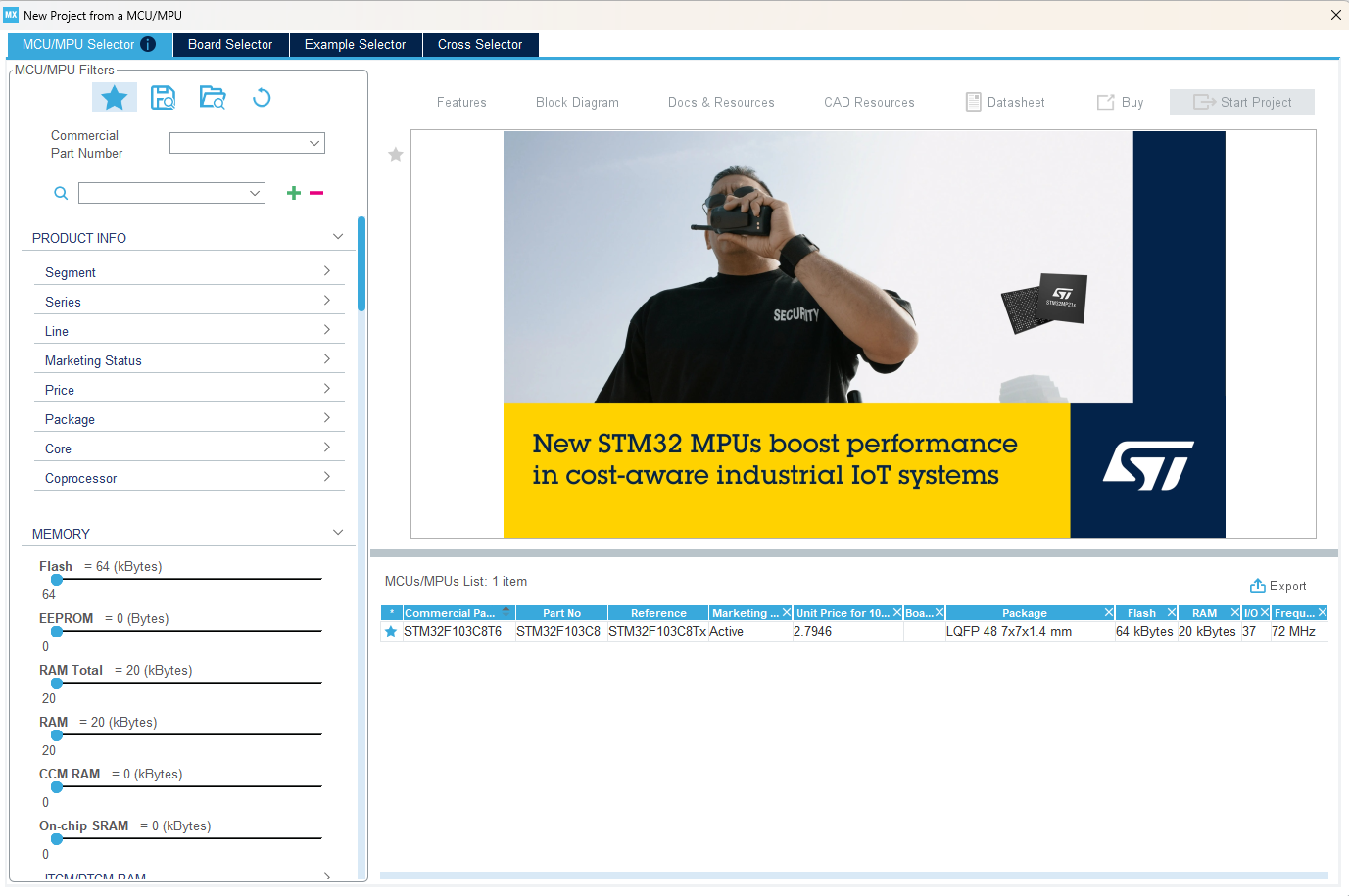

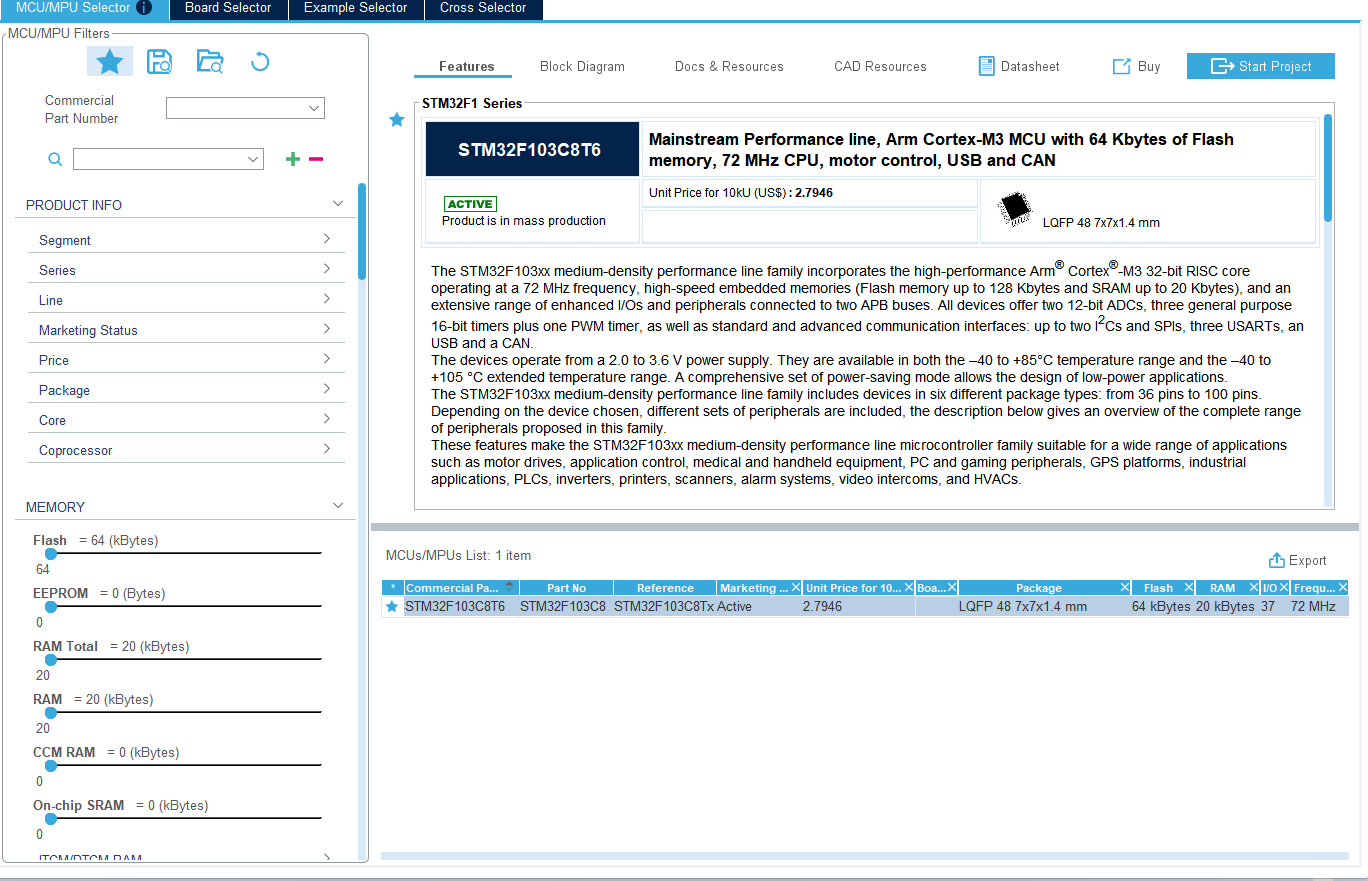

点击左上角收藏的五角星,再点击右下角收藏的芯片stm32f103c8t6

点击右上角的start project开始工程

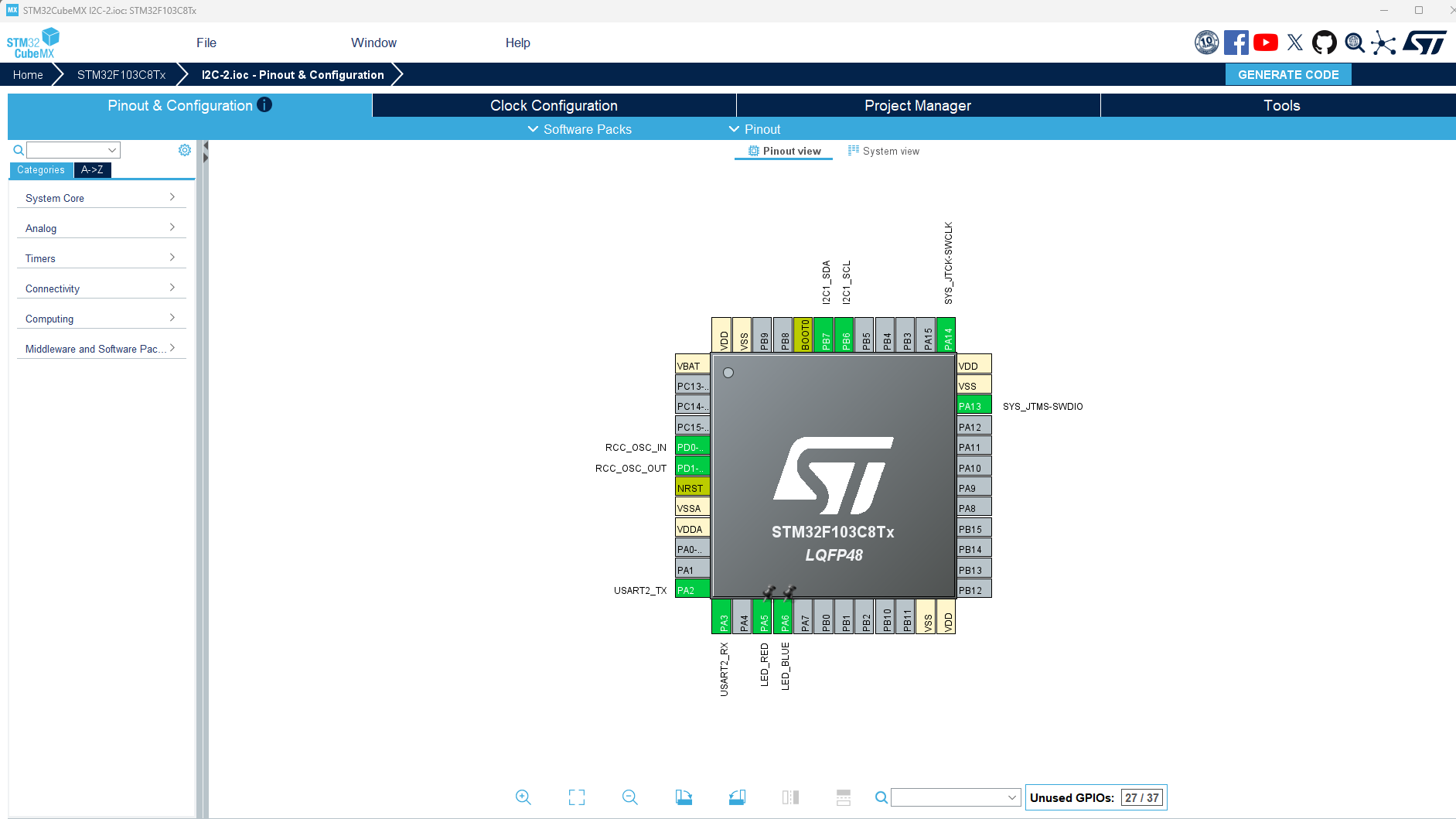

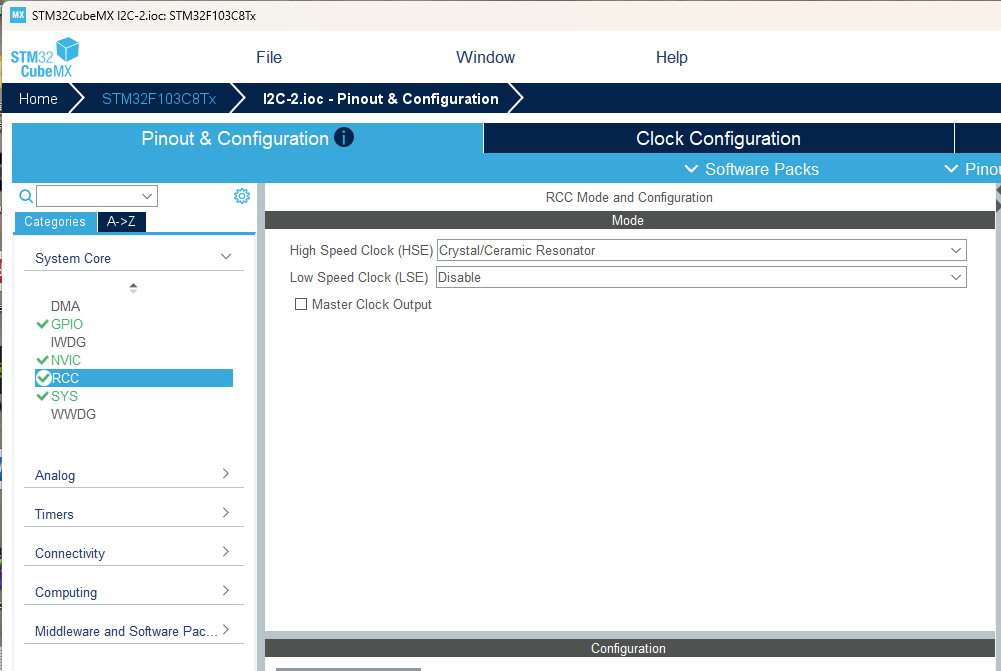

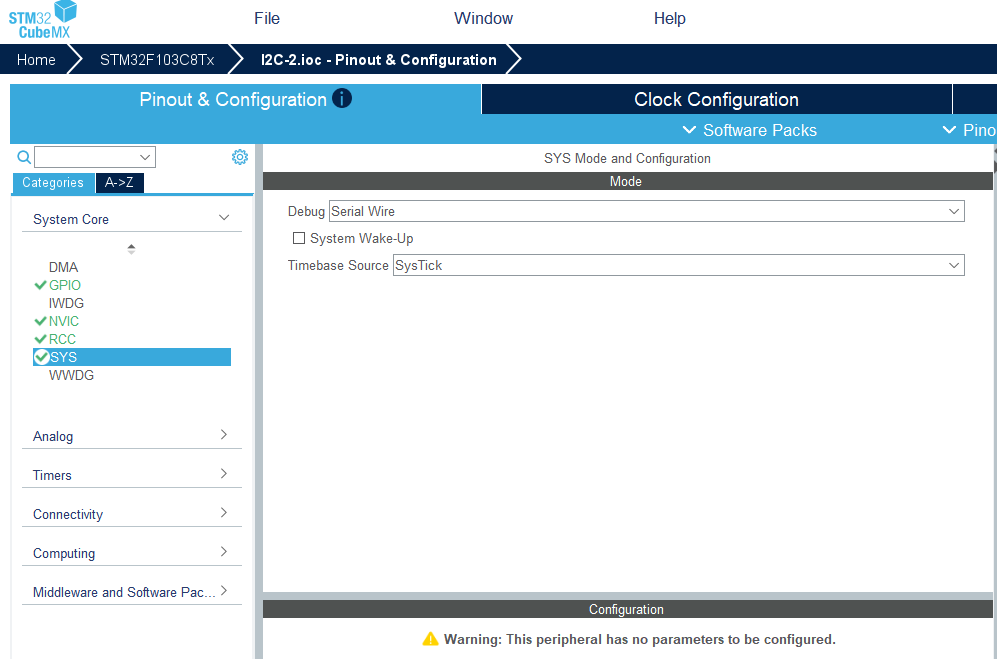

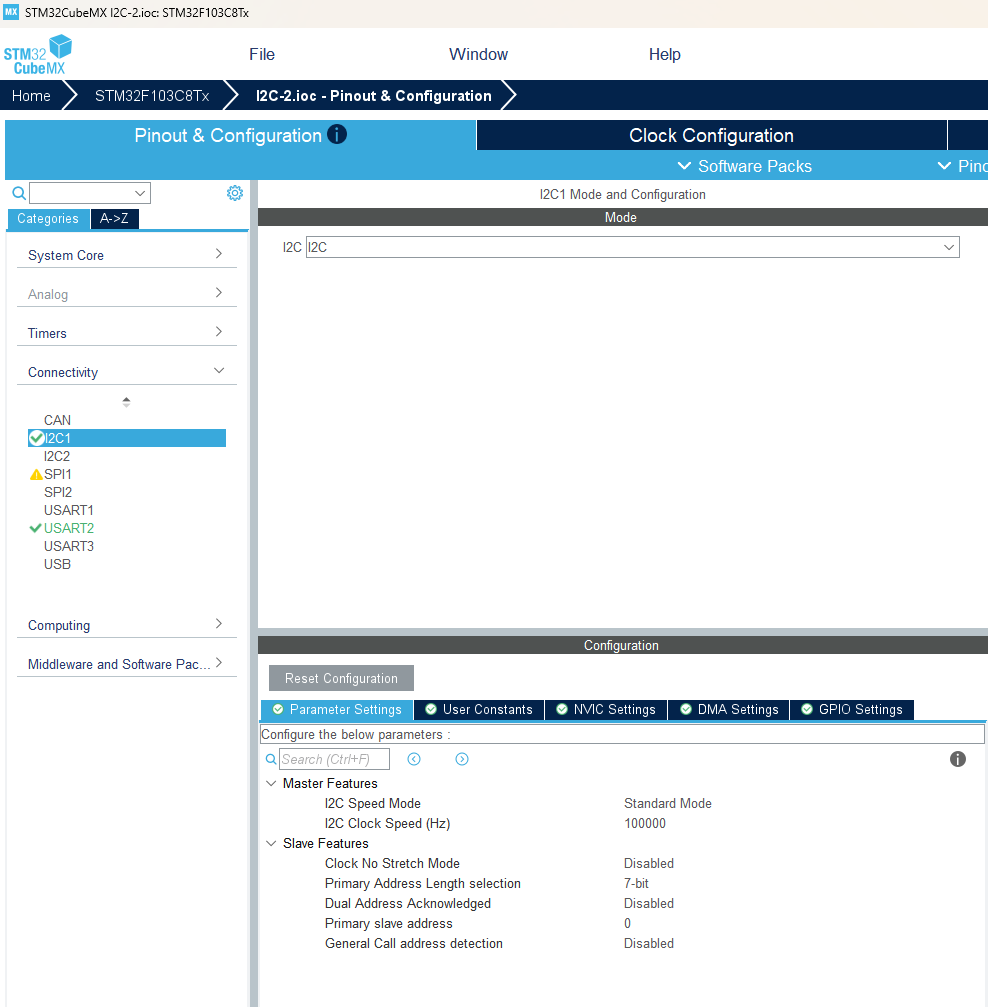

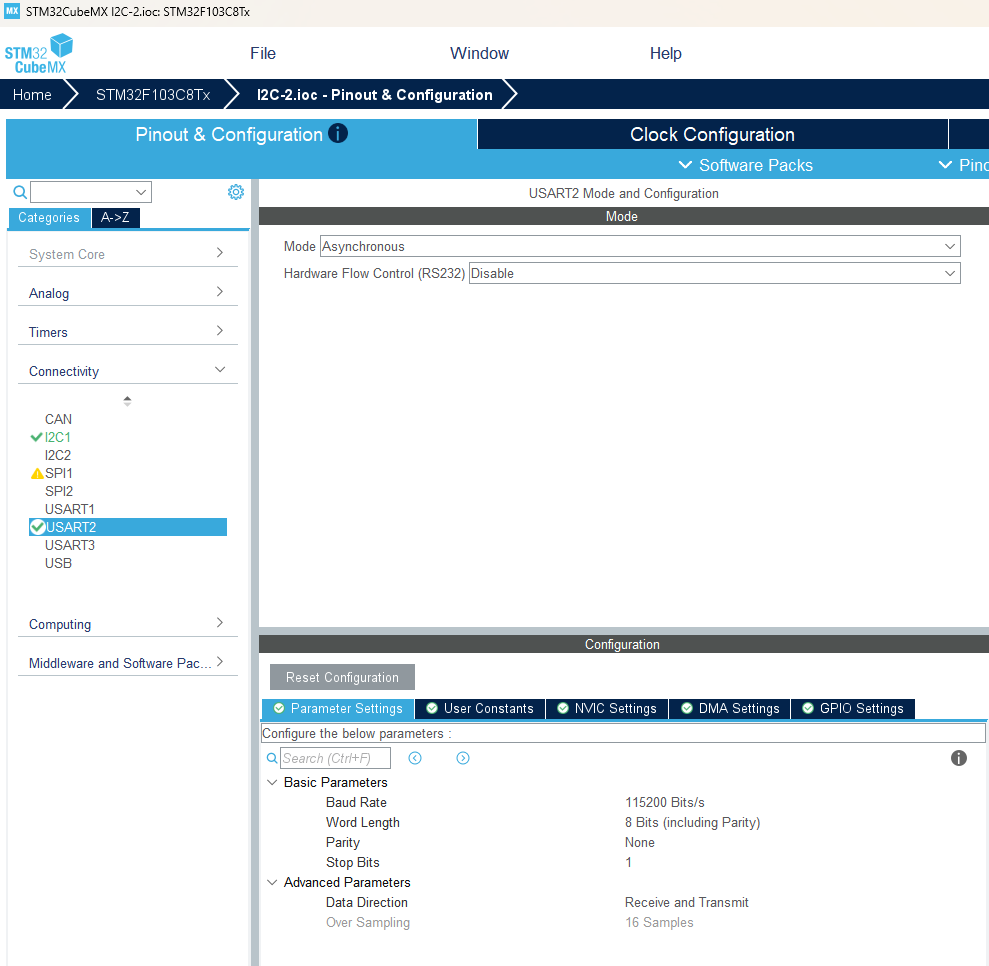

按照下面的配置操作:

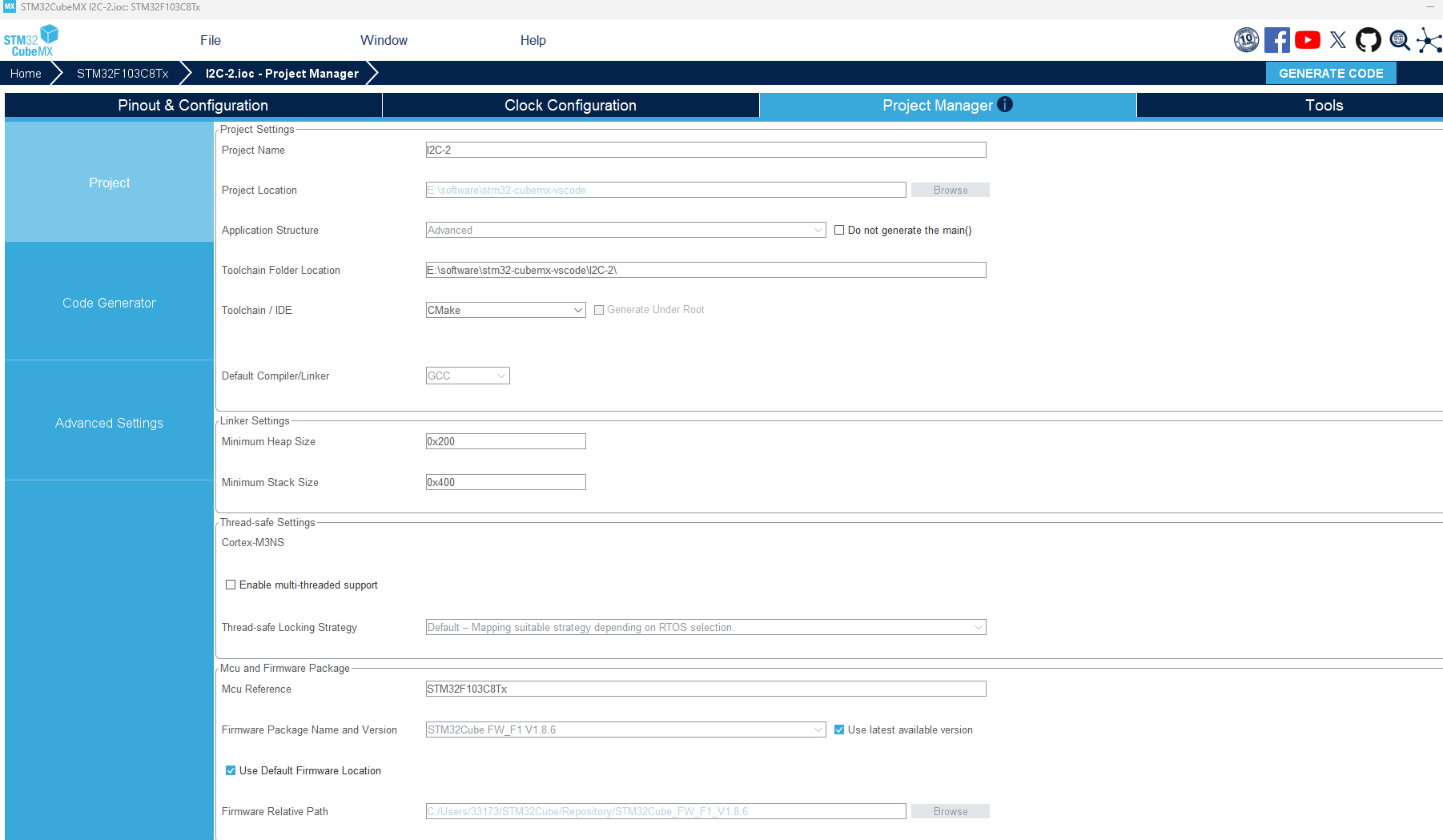

一定要注意选择CMake(用vscode或qoder来打开),选择MDK-ARM就是用keil打开。最后点击右上角的GENERATE CODE来生成代码。配置好vscode,安装好qoder,在安装的过程中选择参考vscode,后面就能在qoder里面来打开vscode的工程。

在qoder里面打开文件夹

ctrl+l开启右侧的AI(也可以在vscode里面安装比如千问、trae等AI插件,然后直接在vscode里面操作,就不用下载qoder)。在qoder里面打开工程:

ctrl+l开启右侧的AI(也可以在vscode里面安装比如千问、trae等AI插件,然后直接在vscode里面操作,就不用下载qoder)。在qoder里面打开工程:

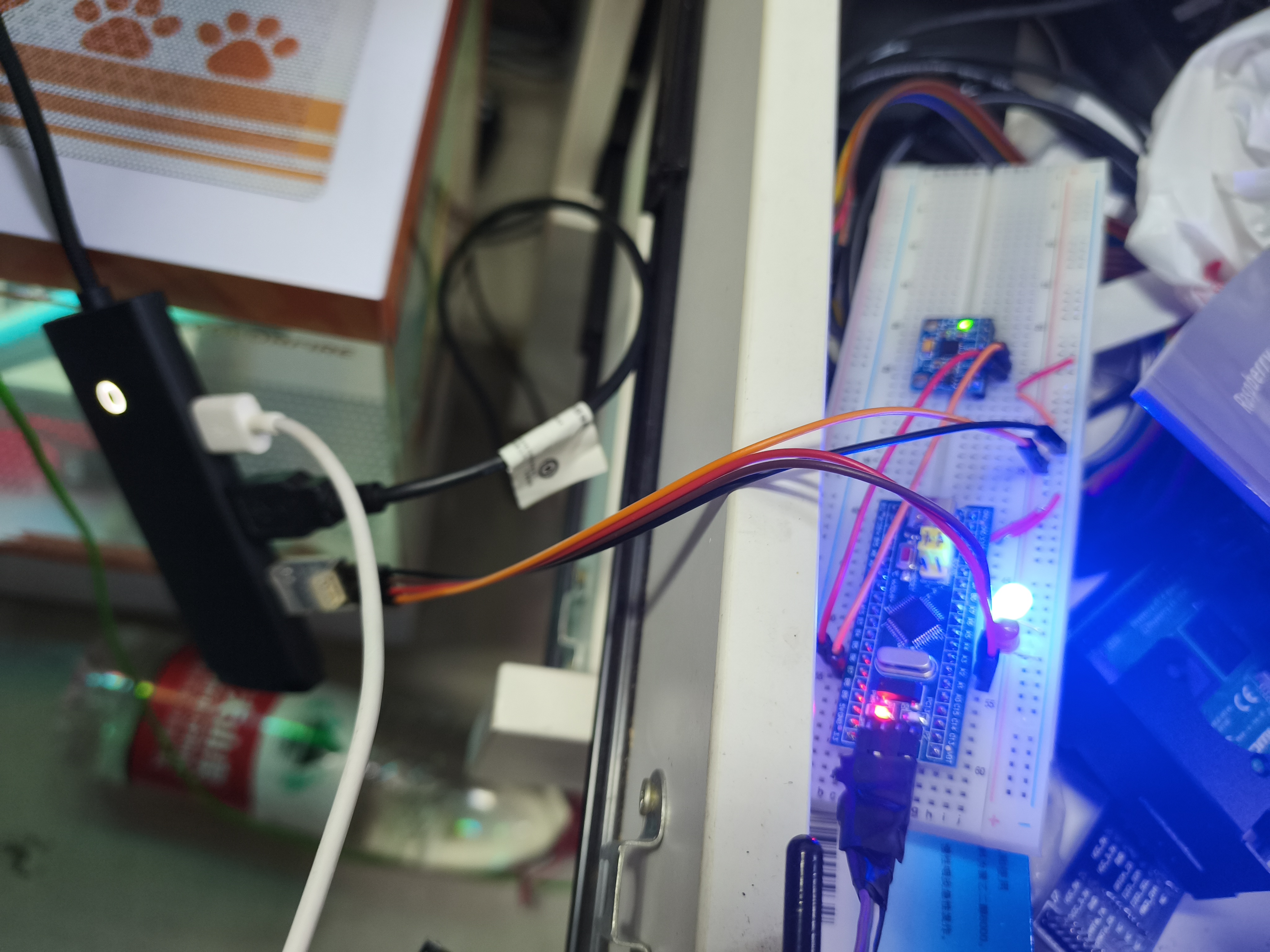

会生成基本的配置,接下来需要连接好mpu6050和单片机,连接好单片机和TTL转USB模块,连接好红蓝两个小灯(注意引脚,单片机输出两个高电平,所以灯的长的引脚接单片机引脚,短的接地)。

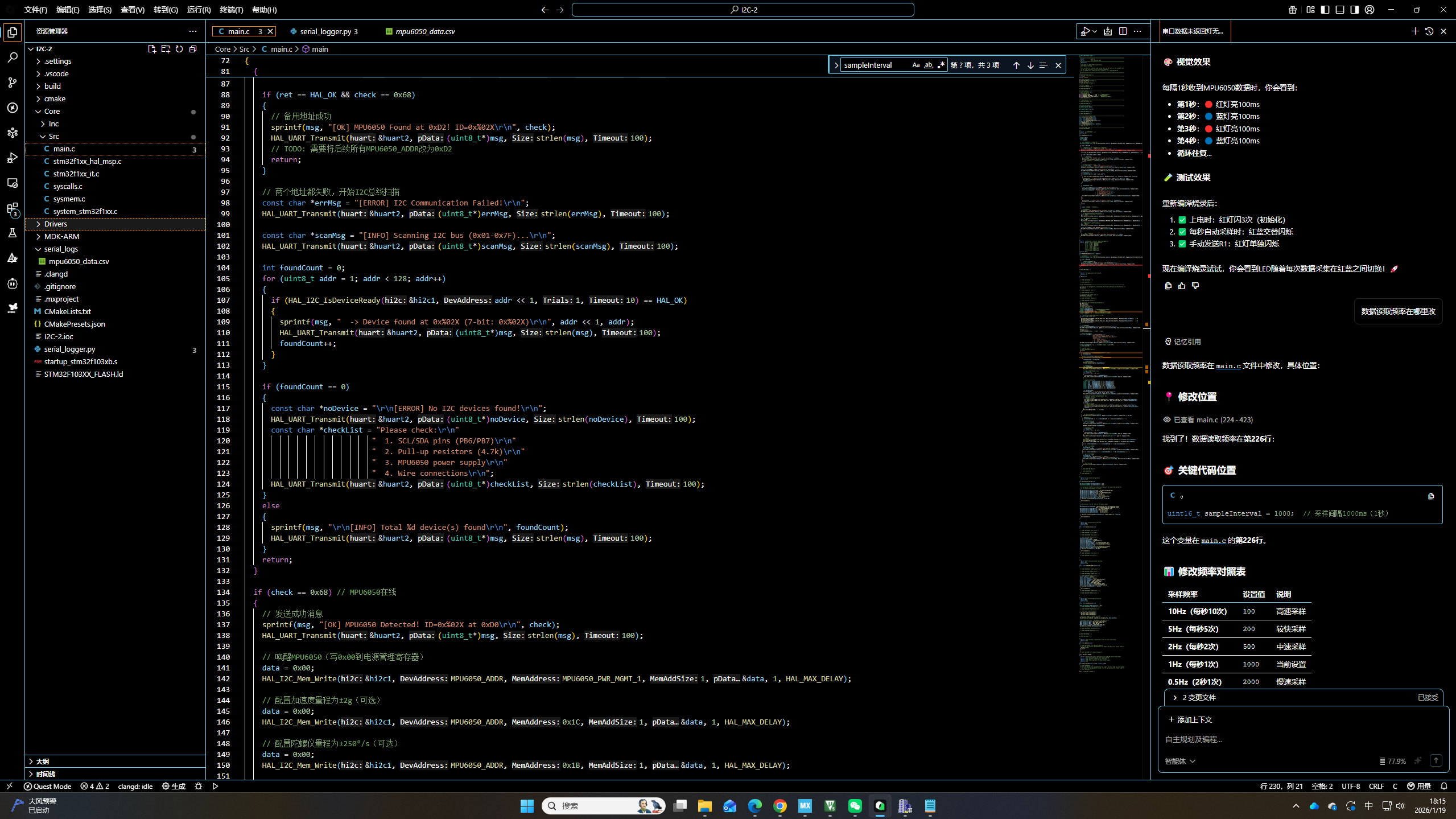

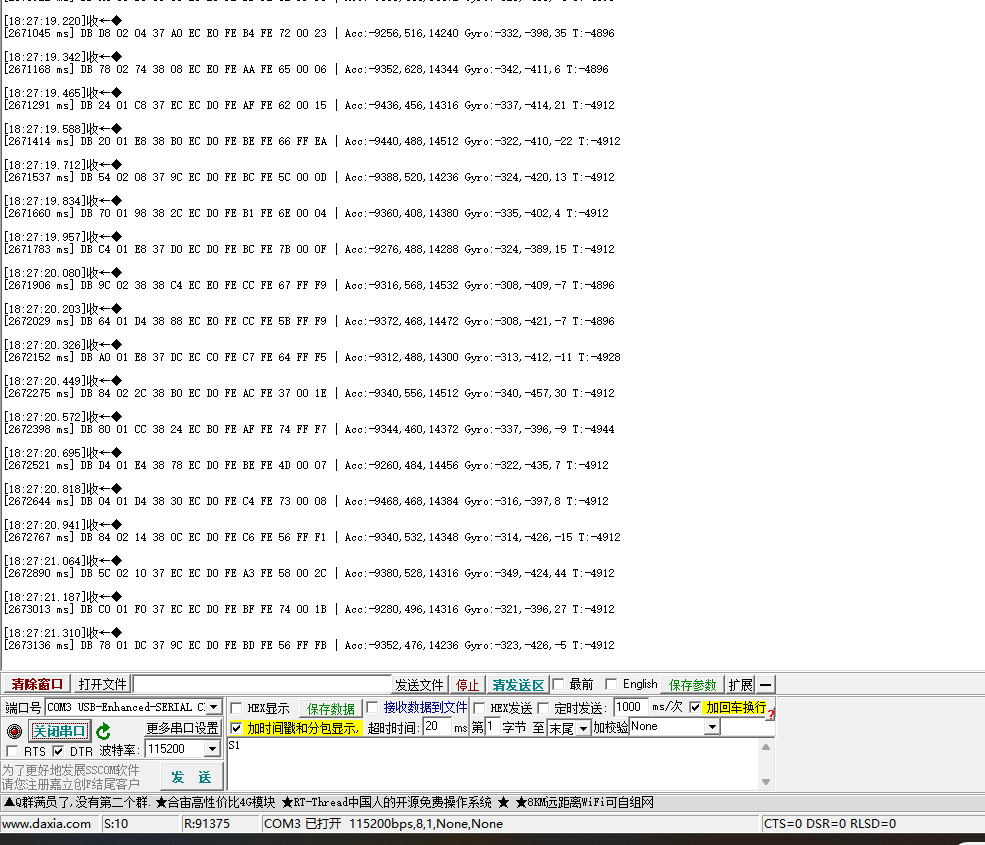

main.c文件里面,让AI采集传感器的数据,然后通过串口发送到电脑,串口软件及对应版本是sscom5.13.1,要选择好端口号、波特率(和在cubemx的要一样)

main.c文件里面,让AI采集传感器的数据,然后通过串口发送到电脑,串口软件及对应版本是sscom5.13.1,要选择好端口号、波特率(和在cubemx的要一样)

main.c如下:(采集数据并串口发送到串口助手,采样频率看这里:uint16_t sampleInterval = 100; // 采样间隔100ms(0.1秒))。写好main.c文件后,在keil里面打开这个工程文件,你每次在qoder里面修改好代码后,你回到keil都会提示代码已经更新,你只需要点击ok就行。接着点击编译,编译通过就行,编译不通过,就将报错复制并粘贴到qoder的右侧,来让AI修改代码,修改完成后,回到keil并点击ok,编译。编译通过后就用STLINK将代码烧录到单片机的flash。按一下单片机最小系统上面的启动按钮,程序就开始运行了,接着,打开上面的串口助手,会以1/100ms的频率输出数据到串口助手。

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* Copyright (c) 2026 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

/* Private includes ----------------------------------------------------------*/

/* USER CODE BEGIN Includes */

#include <stdio.h>

/* USER CODE END Includes */

/* Private typedef -----------------------------------------------------------*/

/* USER CODE BEGIN PTD */

/* USER CODE END PTD */

/* Private define ------------------------------------------------------------*/

/* USER CODE BEGIN PD */

// MPU6050地址定义

#define MPU6050_ADDR 0xD0 // 7位地址0x68左移1位

#define MPU6050_PWR_MGMT_1 0x6B // 电源管理寄存器

#define MPU6050_ACCEL_XOUT_H 0x3B // 加速度数据起始寄存器

/* USER CODE END PD */

/* Private macro -------------------------------------------------------------*/

/* USER CODE BEGIN PM */

/* USER CODE END PM */

/* Private variables ---------------------------------------------------------*/

I2C_HandleTypeDef hi2c1;

UART_HandleTypeDef huart2;

/* USER CODE BEGIN PV */

/* USER CODE END PV */

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

static void MX_GPIO_Init(void);

static void MX_I2C1_Init(void);

static void MX_USART2_UART_Init(void);

/* USER CODE BEGIN PFP */

void MPU6050_Init(void);

void MPU6050_ReadData(uint8_t *buffer);

/* USER CODE END PFP */

/* Private user code ---------------------------------------------------------*/

/* USER CODE BEGIN 0 */

/**

* @brief 初始化MPU6050传感器

* @retval None

*/

void MPU6050_Init(void)

{

uint8_t check;

uint8_t data;

char msg[80];

// 尝试主地址0xD0 (7位地址0x68)

HAL_StatusTypeDef ret = HAL_I2C_Mem_Read(&hi2c1, MPU6050_ADDR, 0x75, 1, &check, 1, 100);

if (ret != HAL_OK)

{

// 主地址失败,尝试备用地址0xD2 (7位地址0x69)

const char *tryMsg = "[INFO] 0xD0 failed, trying 0xD2...\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)tryMsg, strlen(tryMsg), 100);

ret = HAL_I2C_Mem_Read(&hi2c1, 0xD2, 0x75, 1, &check, 1, 100);

if (ret == HAL_OK && check == 0x68)

{

// 备用地址成功

sprintf(msg, "[OK] MPU6050 Found at 0xD2! ID=0x%02X\r\n", check);

HAL_UART_Transmit(&huart2, (uint8_t*)msg, strlen(msg), 100);

// TODO: 需要将后续所有MPU6050_ADDR改为0xD2

return;

}

// 两个地址都失败,开始I2C总线扫描

const char *errMsg = "[ERROR] I2C Communication Failed!\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)errMsg, strlen(errMsg), 100);

const char *scanMsg = "[INFO] Scanning I2C bus (0x01-0x7F)...\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)scanMsg, strlen(scanMsg), 100);

int foundCount = 0;

for (uint8_t addr = 1; addr < 128; addr++)

{

if (HAL_I2C_IsDeviceReady(&hi2c1, addr << 1, 1, 10) == HAL_OK)

{

sprintf(msg, " -> Device found at 0x%02X (7-bit: 0x%02X)\r\n", addr << 1, addr);

HAL_UART_Transmit(&huart2, (uint8_t*)msg, strlen(msg), 100);

foundCount++;

}

}

if (foundCount == 0)

{

const char *noDevice = "\r\n[ERROR] No I2C devices found!\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)noDevice, strlen(noDevice), 100);

const char *checkList = "Please check:\r\n"

" 1. SCL/SDA pins (PB6/PB7)\r\n"

" 2. Pull-up resistors (4.7k)\r\n"

" 3. MPU6050 power supply\r\n"

" 4. Wire connections\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)checkList, strlen(checkList), 100);

}

else

{

sprintf(msg, "\r\n[INFO] Total %d device(s) found\r\n", foundCount);

HAL_UART_Transmit(&huart2, (uint8_t*)msg, strlen(msg), 100);

}

return;

}

if (check == 0x68) // MPU6050在线

{

// 发送成功消息

sprintf(msg, "[OK] MPU6050 Detected! ID=0x%02X at 0xD0\r\n", check);

HAL_UART_Transmit(&huart2, (uint8_t*)msg, strlen(msg), 100);

// 唤醒MPU6050(写0x00到电源管理寄存器)

data = 0x00;

HAL_I2C_Mem_Write(&hi2c1, MPU6050_ADDR, MPU6050_PWR_MGMT_1, 1, &data, 1, HAL_MAX_DELAY);

// 配置加速度量程为±2g(可选)

data = 0x00;

HAL_I2C_Mem_Write(&hi2c1, MPU6050_ADDR, 0x1C, 1, &data, 1, HAL_MAX_DELAY);

// 配置陀螺仪量程为±250°/s(可选)

data = 0x00;

HAL_I2C_Mem_Write(&hi2c1, MPU6050_ADDR, 0x1B, 1, &data, 1, HAL_MAX_DELAY);

const char *okMsg = "[OK] MPU6050 Initialized!\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)okMsg, strlen(okMsg), 100);

}

else

{

// 检测到设备但ID不对

sprintf(msg, "[ERROR] Wrong Device ID=0x%02X (Expected 0x68)\r\n", check);

HAL_UART_Transmit(&huart2, (uint8_t*)msg, strlen(msg), 100);

}

}

/**

* @brief 读取MPU6050所有数据(加速度+温度+陀螺仪)

* @param buffer: 存储14字节数据的缓冲区

* [0-1]: AccX (加速度X轴)

* [2-3]: AccY (加速度Y轴)

* [4-5]: AccZ (加速度Z轴)

* [6-7]: Temp (温度)

* [8-9]: GyroX (陀螺仪X轴)

* [10-11]:GyroY (陀螺仪Y轴)

* [12-13]:GyroZ (陀螺仪Z轴)

* @retval None

*/

void MPU6050_ReadData(uint8_t *buffer)

{

// 从0x3B寄存器开始连续读14字节

HAL_StatusTypeDef ret = HAL_I2C_Mem_Read(&hi2c1, MPU6050_ADDR, MPU6050_ACCEL_XOUT_H, 1, buffer, 14, HAL_MAX_DELAY);

if (ret != HAL_OK)

{

// 读取失败,填充错误标记

const char *errMsg = "[ERROR] Failed to read MPU6050 data!\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)errMsg, strlen(errMsg), 100);

memset(buffer, 0xFF, 14); // 填充0xFF表示错误

}

}

/* USER CODE END 0 */

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_I2C1_Init();

MX_USART2_UART_Init();

/* USER CODE BEGIN 2 */

uint8_t receivedata[2];

uint8_t mpu6050Data[14]; // 存储MPU6050的14字节数据

uint32_t lastSampleTime = 0; // 上次采样时间

uint16_t sampleInterval = 100; // 采样间隔100ms(1秒)

uint8_t ledState = 0; // LED状态(0=红灯亮,1=蓝灯亮)

// 测试LED:上电后红灯闪3次,证明程序在运行

for (int i = 0; i < 3; i++)

{

HAL_GPIO_WritePin(LED_RED_GPIO_Port, LED_RED_Pin, GPIO_PIN_RESET); // 亮

HAL_Delay(200);

HAL_GPIO_WritePin(LED_RED_GPIO_Port, LED_RED_Pin, GPIO_PIN_SET); // 灭

HAL_Delay(200);

}

// 初始化MPU6050

const char *initStartMsg = "\r\n=== System Initializing ===\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)initStartMsg, strlen(initStartMsg), 100);

MPU6050_Init();

HAL_Delay(100); // 等待传感器稳定

// 发送初始化完成提示

const char *initMsg = "\r\nSystem Ready!\r\n"

"Auto sampling every 1 second...\r\n"

"LED will toggle RED/BLUE on each data\r\n"

"Commands:\r\n"

" R1 - Manual read\r\n"

" S0 - Stop auto sampling\r\n"

" S1 - Start auto sampling\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)initMsg, strlen(initMsg), 100);

uint8_t autoSampling = 1; // 自动采样标志(1=开启,0=关闭)

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

// 自动采样模式:每隔sampleInterval毫秒采集一次数据

if (autoSampling)

{

uint32_t currentTime = HAL_GetTick();

if (currentTime - lastSampleTime >= sampleInterval)

{

lastSampleTime = currentTime;

// 读取MPU6050数据

MPU6050_ReadData(mpu6050Data);

// 发送时间戳

char timeBuf[40];

sprintf(timeBuf, "\r\n[%lu ms] ", currentTime);

HAL_UART_Transmit(&huart2, (uint8_t*)timeBuf, strlen(timeBuf), 100);

// 发送原始数据(十六进制)

char hexBuf[4];

for (int i = 0; i < 14; i++)

{

sprintf(hexBuf, "%02X ", mpu6050Data[i]);

HAL_UART_Transmit(&huart2, (uint8_t*)hexBuf, 3, 100);

}

// 解析并发送可读数据

int16_t accX = (mpu6050Data[0] << 8) | mpu6050Data[1];

int16_t accY = (mpu6050Data[2] << 8) | mpu6050Data[3];

int16_t accZ = (mpu6050Data[4] << 8) | mpu6050Data[5];

int16_t temp = (mpu6050Data[6] << 8) | mpu6050Data[7];

int16_t gyroX = (mpu6050Data[8] << 8) | mpu6050Data[9];

int16_t gyroY = (mpu6050Data[10] << 8) | mpu6050Data[11];

int16_t gyroZ = (mpu6050Data[12] << 8) | mpu6050Data[13];

char dataBuf[100];

sprintf(dataBuf, "| Acc:%d,%d,%d Gyro:%d,%d,%d T:%d\r\n",

accX, accY, accZ, gyroX, gyroY, gyroZ, temp);

HAL_UART_Transmit(&huart2, (uint8_t*)dataBuf, strlen(dataBuf), 100);

// LED红蓝交替闪烁(每次收到数据切换一次)

if (ledState == 0) {

// 红灯亮,蓝灯灭

HAL_GPIO_WritePin(LED_RED_GPIO_Port, LED_RED_Pin, GPIO_PIN_RESET);

HAL_GPIO_WritePin(LED_BLUE_GPIO_Port, LED_BLUE_Pin, GPIO_PIN_SET);

ledState = 1;

} else {

// 蓝灯亮,红灯灭

HAL_GPIO_WritePin(LED_RED_GPIO_Port, LED_RED_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(LED_BLUE_GPIO_Port, LED_BLUE_Pin, GPIO_PIN_RESET);

ledState = 0;

}

HAL_Delay(100); // 保持100ms

}

}

// 检查是否有串口指令(非阻塞接收)

if (HAL_UART_Receive(&huart2, receivedata, 2, 10) == HAL_OK)

{

// 判断指令类型

if ((receivedata[0] == 'R' || receivedata[0] == 'r') && receivedata[1] == '1')

{

// 【手动读取模式】

const char *readMsg = "\r\n[MANUAL] ";

HAL_UART_Transmit(&huart2, (uint8_t*)readMsg, strlen(readMsg), 100);

MPU6050_ReadData(mpu6050Data);

// 发送十六进制数据

char hexBuf[4];

for (int i = 0; i < 14; i++)

{

sprintf(hexBuf, "%02X ", mpu6050Data[i]);

HAL_UART_Transmit(&huart2, (uint8_t*)hexBuf, 3, 100);

}

HAL_UART_Transmit(&huart2, (uint8_t*)"\r\n", 2, 100);

// LED闪烁

HAL_GPIO_WritePin(LED_RED_GPIO_Port, LED_RED_Pin, GPIO_PIN_RESET);

HAL_Delay(100);

HAL_GPIO_WritePin(LED_RED_GPIO_Port, LED_RED_Pin, GPIO_PIN_SET);

}

else if ((receivedata[0] == 'S' || receivedata[0] == 's') && receivedata[1] == '0')

{

// 【停止自动采样】

autoSampling = 0;

const char *stopMsg = "\r\n[INFO] Auto sampling STOPPED\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)stopMsg, strlen(stopMsg), 100);

}

else if ((receivedata[0] == 'S' || receivedata[0] == 's') && receivedata[1] == '1')

{

// 【启动自动采样】

autoSampling = 1;

lastSampleTime = HAL_GetTick(); // 重置时间

const char *startMsg = "\r\n[INFO] Auto sampling STARTED\r\n";

HAL_UART_Transmit(&huart2, (uint8_t*)startMsg, strlen(startMsg), 100);

}

else

{

// 【回环模式】

HAL_UART_Transmit(&huart2, receivedata, 2, 100);

}

}

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSE;

RCC_OscInitStruct.HSEState = RCC_HSE_ON;

RCC_OscInitStruct.HSEPredivValue = RCC_HSE_PREDIV_DIV1;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSE;

RCC_OscInitStruct.PLL.PLLMUL = RCC_PLL_MUL9;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV2;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_2) != HAL_OK)

{

Error_Handler();

}

}

/**

* @brief I2C1 Initialization Function

* @param None

* @retval None

*/

static void MX_I2C1_Init(void)

{

/* USER CODE BEGIN I2C1_Init 0 */

/* USER CODE END I2C1_Init 0 */

/* USER CODE BEGIN I2C1_Init 1 */

/* USER CODE END I2C1_Init 1 */

hi2c1.Instance = I2C1;

hi2c1.Init.ClockSpeed = 100000;

hi2c1.Init.DutyCycle = I2C_DUTYCYCLE_2;

hi2c1.Init.OwnAddress1 = 0;

hi2c1.Init.AddressingMode = I2C_ADDRESSINGMODE_7BIT;

hi2c1.Init.DualAddressMode = I2C_DUALADDRESS_DISABLE;

hi2c1.Init.OwnAddress2 = 0;

hi2c1.Init.GeneralCallMode = I2C_GENERALCALL_DISABLE;

hi2c1.Init.NoStretchMode = I2C_NOSTRETCH_DISABLE;

if (HAL_I2C_Init(&hi2c1) != HAL_OK)

{

Error_Handler();

}

/* USER CODE BEGIN I2C1_Init 2 */

/* USER CODE END I2C1_Init 2 */

}

/**

* @brief USART2 Initialization Function

* @param None

* @retval None

*/

static void MX_USART2_UART_Init(void)

{

/* USER CODE BEGIN USART2_Init 0 */

/* USER CODE END USART2_Init 0 */

/* USER CODE BEGIN USART2_Init 1 */

/* USER CODE END USART2_Init 1 */

huart2.Instance = USART2;

huart2.Init.BaudRate = 115200;

huart2.Init.WordLength = UART_WORDLENGTH_8B;

huart2.Init.StopBits = UART_STOPBITS_1;

huart2.Init.Parity = UART_PARITY_NONE;

huart2.Init.Mode = UART_MODE_TX_RX;

huart2.Init.HwFlowCtl = UART_HWCONTROL_NONE;

huart2.Init.OverSampling = UART_OVERSAMPLING_16;

if (HAL_UART_Init(&huart2) != HAL_OK)

{

Error_Handler();

}

/* USER CODE BEGIN USART2_Init 2 */

/* USER CODE END USART2_Init 2 */

}

/**

* @brief GPIO Initialization Function

* @param None

* @retval None

*/

static void MX_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

/* USER CODE BEGIN MX_GPIO_Init_1 */

/* USER CODE END MX_GPIO_Init_1 */

/* GPIO Ports Clock Enable */

__HAL_RCC_GPIOD_CLK_ENABLE();

__HAL_RCC_GPIOA_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(GPIOA, LED_RED_Pin|LED_BLUE_Pin, GPIO_PIN_SET);

/*Configure GPIO pins : LED_RED_Pin LED_BLUE_Pin */

GPIO_InitStruct.Pin = LED_RED_Pin|LED_BLUE_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_PULLUP;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct);

/* USER CODE BEGIN MX_GPIO_Init_2 */

/* USER CODE END MX_GPIO_Init_2 */

}

/* USER CODE BEGIN 4 */

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

上面的单片机作为下位机,工作已经全部完成了

我们需要对采集来的数据做一个应用,所以数据不能只在串口助手输出,需要输出到一个文档里面,我这里将数据存储到了一个csv文件,当然你也可以将数据存储到txt等其他文件里面。

存储数据到mpu6050_data.csv文件里面需要编写python程序serial_logger.py,当然这个程序也可以用c/c++,serial_logger.py代码如下:

#!/usr/bin/env python3

# -*- coding: utf-8 -*-

"""

STM32 MPU6050 串口数据记录器 (CSV格式)

自动保存串口数据到CSV文件,支持实时显示和Excel分析

"""

import serial

import time

from datetime import datetime

import os

import re

import csv

# ==================== 配置参数 ====================

SERIAL_PORT = 'COM3' # 修改为你的串口号(Windows: COM3, Linux: /dev/ttyUSB0)

BAUD_RATE = 115200

SAVE_DIR = 'serial_logs' # 保存目录

FILE_PREFIX = 'mpu6050_data' # 文件名前缀

# ==================== 创建保存目录 ====================

if not os.path.exists(SAVE_DIR):

os.makedirs(SAVE_DIR)

print(f"[INFO] 创建目录: {SAVE_DIR}")

# ==================== 生成文件名 ====================

timestamp = datetime.now().strftime("%Y%m%d_%H%M%S")

filename = os.path.join(SAVE_DIR, f"{FILE_PREFIX}.csv")

print("=" * 60)

print(" STM32 MPU6050 串口数据记录器")

print("=" * 60)

print(f"串口: {SERIAL_PORT}")

print(f"波特率: {BAUD_RATE}")

print(f"保存文件: {filename}")

print("=" * 60)

print("按 Ctrl+C 停止记录\n")

# ==================== 打开串口和文件 ====================

line_count = 0 # 初始化计数器

try:

ser = serial.Serial(SERIAL_PORT, BAUD_RATE, timeout=1)

print(f"[OK] 串口已打开: {SERIAL_PORT}")

with open(filename, 'w', encoding='utf-8-sig', newline='') as f:

# 创建CSV写入器

csv_writer = csv.writer(f)

# 写入CSV表头

csv_writer.writerow([

'PC时间', 'MCU时间(ms)',

'AccX', 'AccY', 'AccZ',

'GyroX', 'GyroY', 'GyroZ',

'Temp',

'原始数据'

])

f.flush()

print(f"\n[OK] CSV表头已写入")

print(f"表头: PC时间, MCU时间, AccX, AccY, AccZ, GyroX, GyroY, GyroZ, Temp, 原始数据\n")

line_count = 0

# 主循环:读取并保存数据

while True:

if ser.in_waiting > 0:

try:

# 读取一行数据

line = ser.readline().decode('utf-8', errors='ignore').strip()

if line and '[' in line and 'ms]' in line:

# 添加PC时间戳

pc_time = datetime.now().strftime('%Y-%m-%d %H:%M:%S.%f')[:-3]

# 解析数据:提取MCU时间戳和传感器数值

# 格式: [7377 ms] DF 00 ... | Acc:-8448,-68,14848 Gyro:-310,-414,-4 T:-4832

# 提取MCU时间

mcu_time_match = re.search(r'\[(\d+) ms\]', line)

mcu_time = mcu_time_match.group(1) if mcu_time_match else ''

# 提取原始十六进制数据

hex_match = re.search(r'\] ([0-9A-F ]+) \|', line)

hex_data = hex_match.group(1) if hex_match else ''

# 提取加速度数据 Acc:x,y,z

acc_match = re.search(r'Acc:(-?\d+),(-?\d+),(-?\d+)', line)

if acc_match:

acc_x = acc_match.group(1)

acc_y = acc_match.group(2)

acc_z = acc_match.group(3)

else:

acc_x = acc_y = acc_z = ''

# 提取陀螺仪数据 Gyro:x,y,z

gyro_match = re.search(r'Gyro:(-?\d+),(-?\d+),(-?\d+)', line)

if gyro_match:

gyro_x = gyro_match.group(1)

gyro_y = gyro_match.group(2)

gyro_z = gyro_match.group(3)

else:

gyro_x = gyro_y = gyro_z = ''

# 提取温度数据 T:value

temp_match = re.search(r'T:(-?\d+)', line)

temp = temp_match.group(1) if temp_match else ''

# 写入CSV行

csv_writer.writerow([

pc_time, mcu_time,

acc_x, acc_y, acc_z,

gyro_x, gyro_y, gyro_z,

temp,

hex_data

])

f.flush() # 立即刷新到文件

# 终端显示(美化输出)

print(f"[{line_count+1:04d}] {pc_time} | MCU:{mcu_time:>6}ms | "

f"Acc:({acc_x:>6},{acc_y:>6},{acc_z:>6}) | "

f"Gyro:({gyro_x:>4},{gyro_y:>4},{gyro_z:>4}) | T:{temp:>5}")

line_count += 1

# 每50行提示一次

if line_count % 50 == 0:

print(f"\n[INFO] ✅ 已记录 {line_count} 行数据到CSV\n")

elif line: # 其他信息行(如初始化信息)

print(f"[INFO] {line}")

except UnicodeDecodeError:

print("[WARNING] 解码错误,跳过此行")

continue

except Exception as e:

print(f"[WARNING] 数据解析错误: {e}")

continue

time.sleep(0.01) # 短暂休眠,降低CPU占用

except serial.SerialException as e:

print(f"[ERROR] 串口错误: {e}")

print(f"[TIP] 请检查:")

print(f" 1. 串口号是否正确(当前: {SERIAL_PORT})")

print(f" 2. 设备是否已连接")

print(f" 3. 串口是否被其他程序占用")

except KeyboardInterrupt:

print("\n\n[INFO] 用户中断,正在保存...")

finally:

try:

if ser.is_open:

ser.close()

print(f"[OK] 串口已关闭")

except:

pass

print(f"[OK] 数据已保存到: {filename}")

print(f"[INFO] 共记录 {line_count} 行数据")

print("\n程序结束")

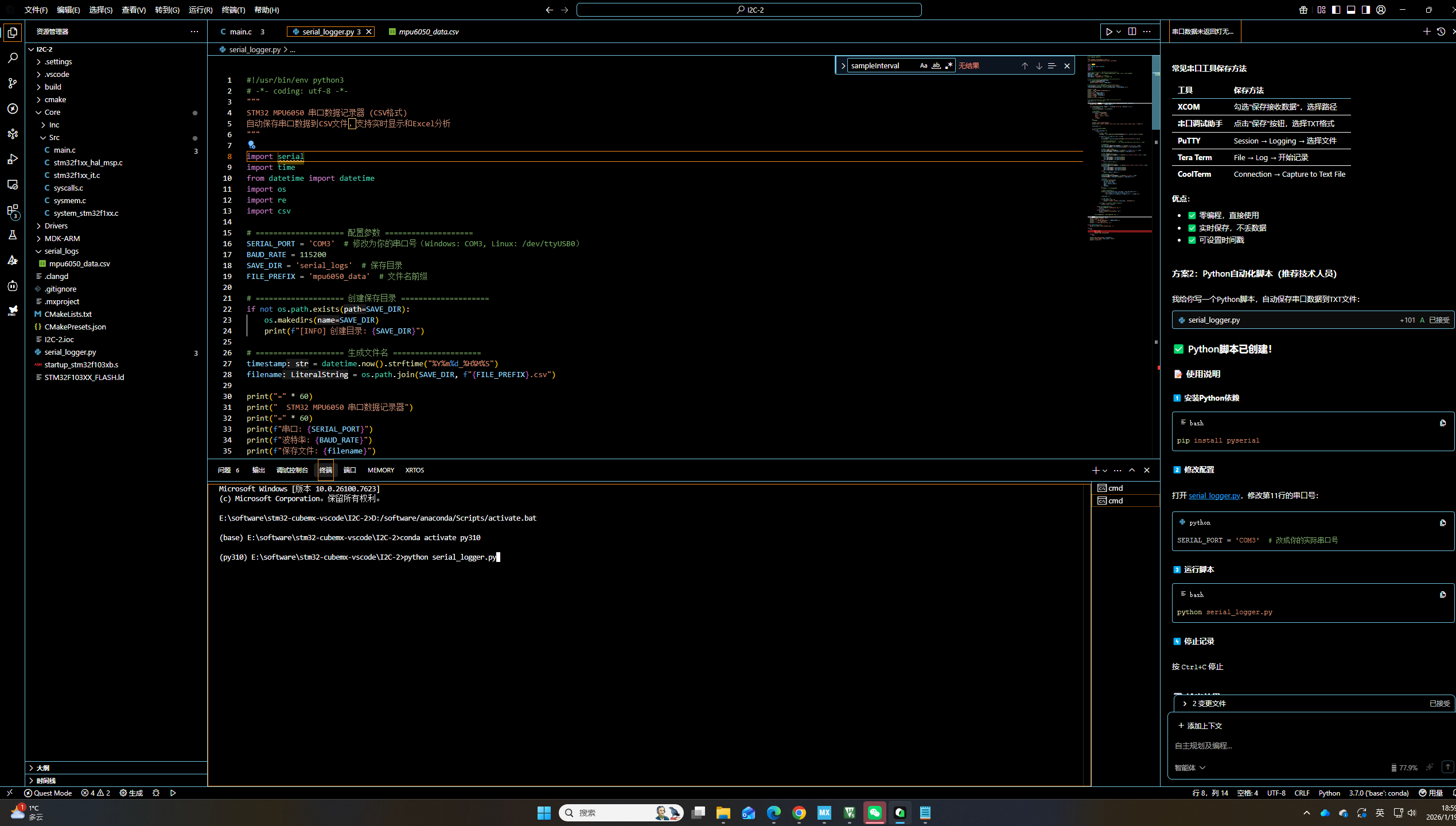

在运行python代码之前,我们需要安装一个环境,来放我们用到的库。首先我们需要在电脑(或者开发板)上(带windows或者ubuntu系统)安装好anaconda,anaconda自带python编译器,就不用安装python编译器了。在终端用

conda create -n mpu6050 python=3.10来创建一个名为mpu6050的环境,这个环境里面安装好了我们写的3.10版本的python,注意python=3.10的等号前后不能有空格。

安装好环境后,在终端用

conda activate mpu6050来进入我们创建的环境,目前我们的环境里面只有版本为3.10的python,我们的python文件里面代码显示需要安装下面这些库

以第一个为例:在终端进入环境后,在终端输入

pip install pyserial来安装好库。安装好每个库以后,由于下位机一直在运行,我们需要启动上位机程序,来记录数据到文件里面。在终端进入环境后输入

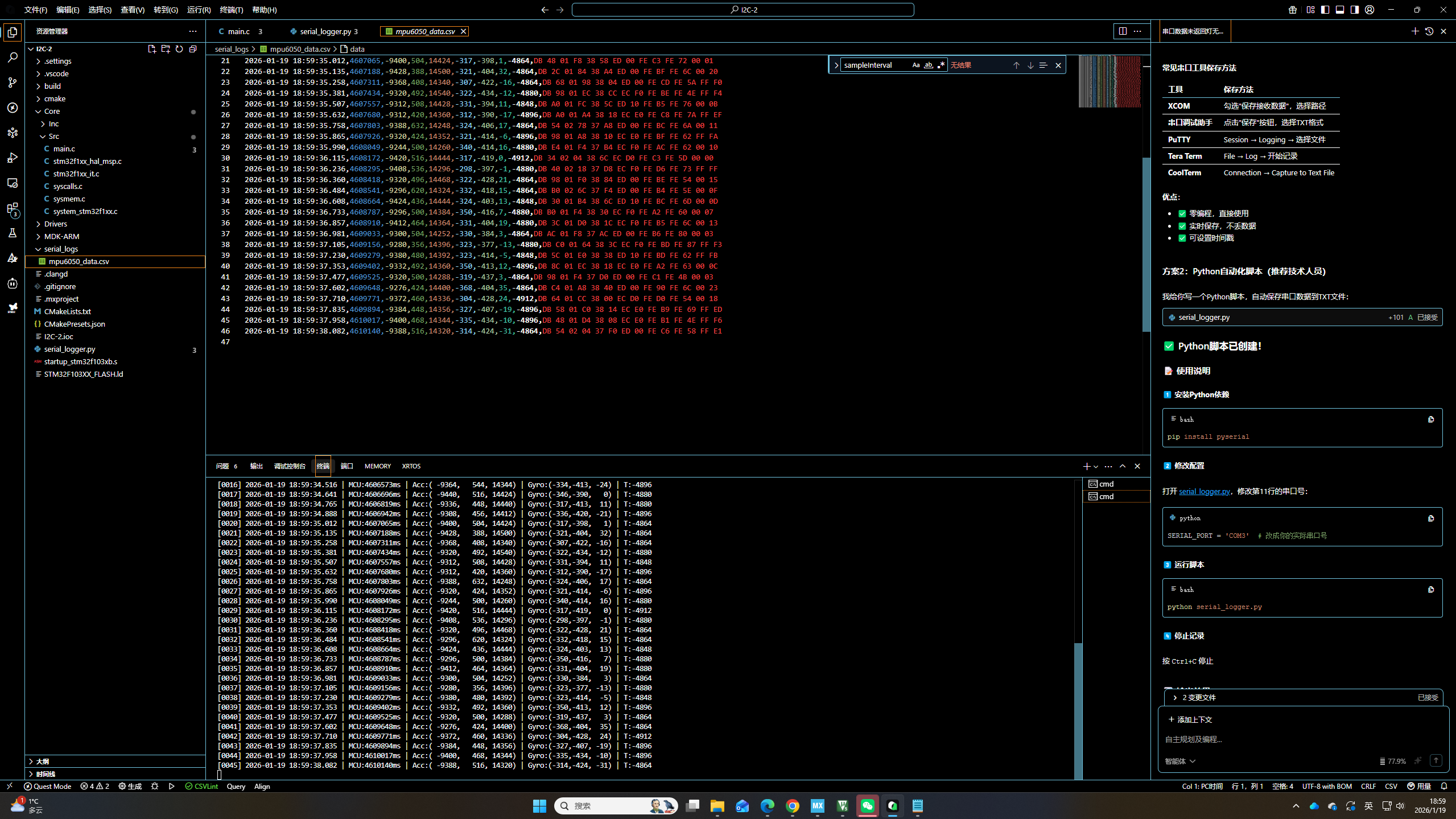

python serial_logger.py来执行上位机的数据存储程序。数据会被存储到serial_logs\mpu6050_data.csv文件里面,效果如下:

按下回车键后,我们会看到终端和存储文件里面在实时记录传感器的数据:

上位机的数据存储已经完成,你可以对这些数据做卡尔曼滤波,可以将滤波后的数据作为神经网络的输入来训练模型,等等。

最后的效果请看我的主页的 视频 作品

更多推荐

已为社区贡献1条内容

已为社区贡献1条内容

所有评论(0)